Introduction

The H-A-S Rotary is designed to produce a three phase power output that will operate both motor and non-motor three phase loads from a single phase power supply. The standard model allows the three phase motors connected to obtain “soft-start” characteristics requiring only approximately 66% of the inrush single phase line current compared to an equivalent HP single phase motor started on the same lines. This inrush (locked rotor current) from the line is approximately the same as if the three phase motor were started on three phase power. The H-A-S Rotary is designed to duplicate three phase power characteristics as closely as possible and maintain reasonable voltage balance with varying loads applied. The H-A-S Rotary accomplishes this due to the rotating transformer construction and appropriate selection of capacitance values. The standard unit includes the capacitor bank securely mounted on the same base with the generator motor. This provides ease of installation and minimum wiring connections in the field.

The H-A-S Rotary is rated with a dual horsepower classification. The first set of digits in the catalog number indicates the largest HP motor to be started while the second set indicates the maximum HP load that may be connected to the H-A-S Rotary. Minimum operating load is 25% of the largest HP motor rating of the converter.

The standard H-A-S Rotary will start motors requiring normal starting torque. If the starting code letter or the inertial loading of the motor is higher than normal, an auxiliary starting panel may be required in order to provide this higher starting torque. Contact the factory for details.

Initial Inspection and Handling

Upon receipt of the H-A-S Rotary, check the carton or crate for damage. Note any signs of damage on appropriate shipping forms. After opening the shipping container, look for concealed damage such as a damaged enclosure or cracked castings. If concealed damage is found, contact the freight carrier and file a claim immediately.

Check the nameplate to verify that the unit conforms to the required specifications.

Safety

Voltage and moving parts involved with electric motors can cause serious injuries; therefore, use extreme care when installing and maintaining electrical equipment of this nature. Become familiar with and follow all local electrical and safety codes as well as the National Electrical Code (NEC) and Occupational Safety & Health Administration (OSHA).

The H-A-S Rotary, as well as the system motors, must be adequately grounded per the NEC (Article 250 – grounding). Before removing any capacitors in the H-A-S Rotary unit, insure that they have been discharged.

Location of Installation

The H-A-S Rotary may be mounted or installed at most any location where it is readily accessible for maintenance. The open dripproof design of the H-A-S Rotary is for use in a dry, clean location with access to an adequate supply of cooling air. For an outdoor installation, the standard unit should be protected with a cover that does not block air flow to the H-A-S Rotary unit. Special units may come fully weatherproof. The H-A-S Rotary should be securely mounted or bolted to a strong flat surface in order to minimize noise and vibration.

GENERAL INSTALLATION INSTRUCTIONS

- The recommended installation includes a main fused d isconnect switch in addition to the motor controls for the individual load motors. Although the individua l motor controls for the load motors are selected the same as for a three phase power system, care must be exercised in selection of the main disconnect switch and wire sizing. Since all the current for the system is obtained from single phase lines, and accounting for the losses of the converter; the amperage draw from the single phase lines will be approximately 2 times the total three phase motor nameplate amperages.

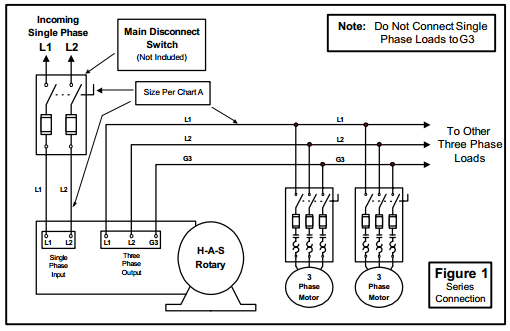

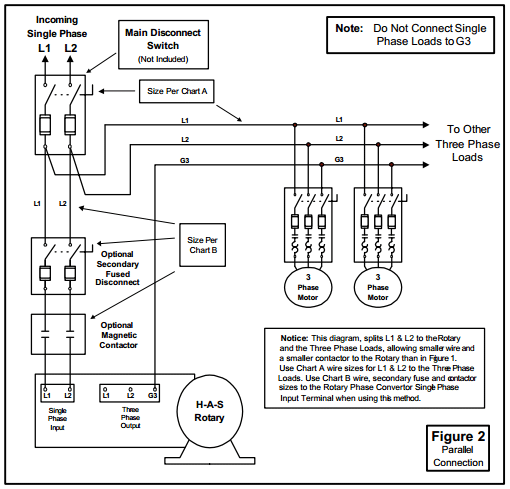

- Install the H-A-S Rotary according to the appropriate wiring diagram (Figure 1 or 2).

- Incoming power (L1 & L2) should be connected through the main disconnect switch and connected to the rotary terminal block, terminals 1 & 2.

- Install the system lines L1, L2, & G3. These may be connected to a three phase distribution panel or looped from motor starter to motor starter.

- Component sizes may be selected fr om Charts A & B.

- Ground all electrical equipment per National Electrical Code (NEC), Article 250.

- The H-A-S Rotary unit must be started and up to speed prior to starting other motors or loads.

- Do not connect any single phase loads to the G3 (gener ated phase) leg. G3 may be identified as the leg with the highest voltage to ground with the Rotary unit operating with no load motors running.

- Do not connect the controls for the motor starters or the contactors to the G3 (generated phase) leg.

- Wire sizing is extremely important in order that prope r voltage may be maintained on the motor start-up. If in doubt, please consult factory.

- If auxiliary starting or running panels are used, it is extremely importa nt that the connections at the auxiliary panel are consistent with connecti ons at the H-A-S Rotary.

- Do not operate the rotary phase converter for long periods of time with less than minimum load. Fifteen minutes is the maximum recommended length of operation of the converter without a load.

General Maintenance Instructions

Before performing any maintenance, disconnect power and allow the H-A-S Rotary unit to come to a complete stop. Dirt accumulations can cause overheating, or a fire hazard, and must be removed. Dirt accumulations around and in vent openings should be removed by vacuuming.

For continuous normal applications, the suggested lubricat ion interval for the H-A-S Rotary is 9 months. Lubricate the H-A-S Rotary as follows:

- For all Rotarys, use a medium polyurea base g rease (typical – Shell Dolium R).

- If motor is equipped with an Alemite fitting, clean the tip of the fitting and apply grease gun. Use 2 full strokes.

- On H-A-S Rotarys having drain plugs, remove grease drain plug and operate converter motor for 20 minutes before replacing drain plug.

Caution: Keep grease clean. Lubricate Rotarys at standstill. Remove and r eplace drain plugs at standstill. Do not mix petroleum grease and silicon grease in rotary bearings.

Troubleshooting Guide

Trouble: Rotary or Load Motor fails to come up to speed

Check main fuses. Fuses should be dual element type.

Check incoming voltage during starting. Voltage should not dip below 210 volts for the 230 volt model and not below 420 volts for the 460 volt model. If the voltage dips below these values, check wire size and transformer KVA.

Check appropriate wiring diagram for improper connections. Single Phase L1 & L2 must be connected to Rotary L1 & L2.

Check inside rotary panel for signs of defective capacitors. If a capacitor has a bulged case, it is defective and should be replaced.

If the load motor has a high starting code letter or is under a high inertia load (large flywheel type), an auxiliary start panel may be required. Consult the factory.

Trouble: Rotary vibrates or is excessively noisy

Check to see if rotary is securely bolted to the floor or surface.

Note: Some noise and vibration is normal, especially under no load conditions. As the rotary is loaded, it will run more quietly.

Trouble: Load Motor Overheats or Generated Voltage is too high when load motor is running

If current is excessive in the G3 generated phase, and voltage across L2 & G3 is high, disconnecting one or more capacitors will lower the generated voltage.

Wiring Diagrams

H-A-S Rotary System Wiring and Device Sizes

Chart A – System Power Requirements

(To be used with both Series and Parallel Connections)

| Total Customer 3 Phase Load (HP) |

Approximate Three Phase Output Amps |

Approximate Single Phase Input Amps |

Minimum Required Utility Transformer KVA |

Required System Service Amps |

Main Disconnect Fuse Size Dual Element |

L1, L2 Minimum Wire Size* |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 230 V | 460 V | 230 V | 460 V | 230 V | 460 V | 230 V | 460 V | 230 V | 460 V | ||

| 3 | 10 | 5 | 20 | 10 | 5 | 30 | 30 | 25 | 15 | 10 | 12 |

| 5 | 15 | 7.5 | 30 | 15 | 5 | 60 | 30 | 40 | 20 | 8 | 10 |

| 7.5 | 22 | 11 | 44 | 22 | 7.5 | 60 | 30 | 50 | 30 | 6 | 10 |

| 10 | 28 | 14 | 56 | 28 | 10 | 100 | 60 | 70 | 40 | 6 | 8 |

| 15 | 42 | 21 | 84 | 42 | 15 | 200 | 60 | 125 | 60 | 1 | 6 |

| 20 | 54 | 27 | 108 | 54 | 25 | 200 | 100 | 150 | 75 | 1/0 | 4 |

| 25 | 68 | 34 | 136 | 68 | 25 | 200 | 100 | 175 | 100 | 2/0 | 3 |

| 30 | 80 | 40 | 160 | 80 | 37.5 | 200 | 100 | 200 | 100 | 3/0 | 3 |

| 40 | 104 | 52 | 208 | 104 | 50 | 400 | 200 | 250 | 125 | 250 | 1 |

| 50 | 130 | 65 | 260 | 130 | 50 | 400 | 200 | 325 | 175 | 350 | 2/0 |

| 60 | 154 | 77 | 308 | 154 | 75 | 400 | 200 | 400 | 200 | 500 | 3/0 |

| 75 | 192 | 96 | 384 | 192 | 75 | 600 | 400 | 500 | 250 | (2) 250 | 250 |

| 100 | 248 | 124 | 496 | 248 | 100 | 800 | 400 | 650 | 350 | (2) 500 | 500 |

| 125 | 312 | 156 | 624 | 312 | 167 | 800 | 400 | 800 | 400 | (2) 500 | 500 |

| 150 | 360 | 180 | 720 | 360 | 167 | 1000 | 600 | 1000 | 500 | (3) 350 | (2) 250 |

| 200 | 480 | 240 | 960 | 480 | 200 | 1200 | 600 | 1200 | 600 | (3) 500 | (2) 350 |

Note: The 1993 National Electrical Code (NEC) requires that your single phase service entrance to three phase operated loads through a phase converter be 2.5 times the full-load three phase amps of the operated equipment, excluding the phase converter. The approximate single phase amps required to operate three phase loads is twice the three phase full load amps.

Chart B – Rotary Component Sizes

(Use only when wiring per Figure 2 [Parallel Connection] along with Chart A for System Requirements.)

| Rotary Model Number (R-Largest HP / Total HP) |

Wire Size** L1, L2 to Rotary (When wired per Fig. 2) |

Optional** Sec. Fused Disconnect Time Delay Fuses (When wired per Fig. 2) |

Optional** NEMA Size Magnetic Contactor (When wired per Fig. 2) |

L1, L2 Wire Size To Three Phase Loads |

||||

|---|---|---|---|---|---|---|---|---|

| Heavy Duty | Light Duty | 230 V | 460 V | 230 V | 460 V | 230 V | 460 V | |

| R-2/4 | 10 | 12 | 15 | 8 | 0 | 0 | See Chart A | |

| R-2/6 | R-3/6 | 10 | 12 | 15 | 8 | 0 | 0 | See Chart A |

| R-3/10 | R-5/10 | 8 | 10 | 30 | 17.5 | 1 | 1 | See Chart A |

| R-5/15 | R-7.5/15 | 8 | 10 | 30 | 17.5 | 1 | 1 | See Chart A |

| R-7.5/20 | R-10/20 | 6 | 8 | 40 | 20 | 2 | 2 | See Chart A |

| R-10/30 | R-15/30 | 6 | 8 | 50 | 25 | 2 | 2 | See Chart A |

| R-15/40 | R-20/40 | 4 | 6 | 75 | 40 | 3 | 2 | See Chart A |

| R-20/50 | R-25/50 | 4 | 6 | 75 | 40 | 3 | 3 | See Chart A |

| R-25/60 | R-30/60 | 3 | 4 | 100 | 50 | 3 | 3 | See Chart A |

| R-30/80 | R-40/80 | 1 | 4 | 125 | 60 | 4 | 3 | See Chart A |

| R-40/100 | R-50/100 | 1/0 | 3 | 150 | 80 | 4 | 3 | See Chart A |

| R-50/120 | R-60/120 | 3/0 | 2 | 200 | 100 | 5 | 4 | See Chart A |

| R-60/150 | R-75/150 | 250 | 1 | 250 | 125 | 5 | 4 | See Chart A |

| R-75/200 | R-100/200 | 350 | 2/0 | 300 | 150 | 5 | 4 | See Chart A |